Wednesday, October 28, 2020

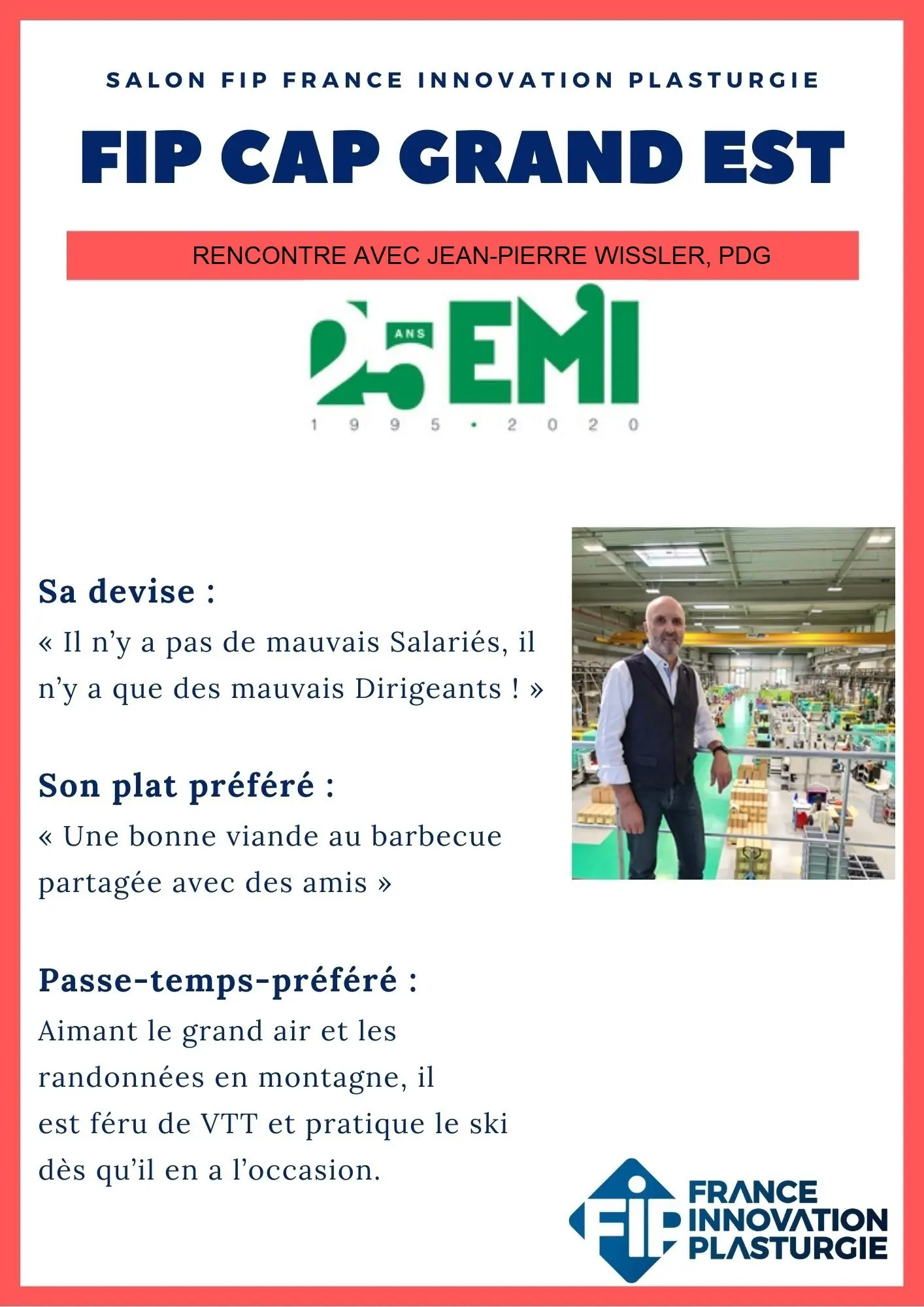

Interview with EMI WISSLER

What are the strengths of your company?

"Being a partner for our customers"

Thanks to our 360° Full Plastic Concept, we offer our customers real support. Each project starts with the study and development of the products, followed by the design and manufacture of the tools, then the injection and overmolding of the parts and finally, we also manage the assembly and validation of the assemblies and sub-assemblies. Afterwards, the measurement and testing laboratory carries out complete controls to guarantee the absolute quality of all parts and assemblies before delivery.

In addition, to ensure a global process, we offer complementary customization activities such as marking, magnetization of ferrites, in-line camera control, specific packaging, etc...

What actions are you implementing for sustainable development?

The 14001 certification testifies to our commitment to reducing our environmental footprint:

- Construction of a building that complies with current regulations (reduction of noise emissions, internalized storage, charging station for electric vehicles, proximity to public transport, etc.)

- Controlled consumption of electrical energy thanks to eco-responsible equipment

- Waste sorting and recovery

- Controlled fire risk thanks to a fully sprinklered building and fire walls

How do you see the evolution of your profession?

Throughout my 35 years of experience in the plastics industry, I have observed a constant evolution of manufacturing methods in order to remain in a process of continuous improvement and innovation to satisfy customer requirements.

From a "material push" job, we have moved on to customer/supplier partnerships in order to develop the most suitable solutions for products.

This has been possible thanks to the evolution of machines, IT (CAD, Rheology, ERP, TRS follow-up) and to the integration of internal development at the plastics manufacturers.

This evolution of the profession continues and it is through a mastery of the production tool and the capacity to innovate that the actors of the plastics industry will continue to evolve.

Where are your markets located?

Our strategy is to concentrate our customers in close proximity, in France, Switzerland and Europe.

What are your outstanding innovations?

We are pioneers in hybrid injection and overmolding of glass-filled thermoplastic materials. We manufacture mass-produced parts in composites also called Organosheet. These materials allow a considerable weight saving while increasing mechanical performances: resistance, functionalization etc....

We also offer innovative solutions in bi-material injection with the mastery of the 4 main technologies: core back, rotary plate, rotary base and transfer.

What are the organizational changes in your company?

Throughout 2017, internal "project" groups were asked to create together, our factory of the future in which we moved in 2018.

Thus, everything has been thought out to facilitate the organization and work of each person, especially for the optimization of the input and output flows:

- Autonomous guided vehicles (AGV)

- Automated material center

- Production monitoring system using Cyclades software

An essential objective is also the implementation of a PLM (Product Lifecycle Management) solution. This process is currently underway and will allow us to develop and manage a version 4.0 product.

In order to continue our development in the medical and paramedical sectors, in the coming months we will increase our level of certification with the ISO 13485 standard. This will allow us to respond even more fully to the constantly changing requirements of medical devices.

Markets: Medical, Electrical, Connections, Renewable energies, Building, Industry, Automotive etc...

Know-how : Specialist in the transformation of thermoplastic and composite materials and the assembly of sets and sub-sets for its customers.

Certifications : ISO 9001, ISO 14001 and UL, ISO 8 clean room, ISO 13485 in progress

Employees: 180, trilingual FR-DE-EN in some departments

Location:

Plant 4.0 of 17,000 m² since 2018

1 avenue Euroeastpark

68300 - Saint-Louis Neuweg

Tel : +33 (0)3 89 70 36 70 Mail : contact@emi-wissler.com